5/27/21 workday

1st job:

Received a call in regards to a GE dishwasher which are not my favorite due to the design which makes it irritating to service. It is a lot of work and the price point on these dishwashers is not very high so it is aggravating.

Anyways, this machine was having an issue with the heating, to check whether it was the board or the heating circuit I ran a diagnostic cycle. My bread and butter is to go straight to the board however this particular design makes removing and reinstalling the board painful, it is a 2-3 hour process, so I strictly use the diagnostic mode on these models.

The error codes indicate the heating circuit is at fault, however there is no reliable way to test a board using the diagnostic cycle, but I have seen in some machines that it may not heat regularly, but if you run a diagnostic cycle the machine will heat. In those cases I replace the board and all is well.

In this case the wire harness which comes with a therm cut off fuse as well as the heating element will be swapped out…

There was also a microwave in the mix with the vent fan not working, but the customer will be replacing as cost of repair is greater than a new one.

2nd job:

This call was in regards to a frigidaire washer making a strange noise upon operation. I ran it through a test cycle and cycled through all of its functions, the washer only makes noise on the spin cycle, which indicates the drain motor is at fault, it may be the main motor as well however the noise persists even if you do a drain cycle without a spin, so it seems highly likely it is only the drain motor.

Frigidaire products are decently built, all of the frigidaire machines I come across are usually 10+ years old, this washer has lasted a while and is better built than the stuff that is on the market today.

The customer is going to order the parts and get back to me when they arrive.

3rd Job:

This job is in regards to a refrigerator sealed system issue, I noticed the evaporator coil was bare but the compressor was silent. The compressor was pretty hot but wasn’t making any noise, so I thought it may have been dead so I stuck a new relay on it nothing changed, and no ice started to form on the evaporator coil so this refrigerator is a lost cause.

4th job:

Another issue with a Refrigerator in regards to the sealed system. This machine also had a bare evaporator coil, and a silent compressor, in this case the compressor was dead cold, I tested 120 volts from the compressor & condensor fan circuit which should be giving out 220 volts according to factor information.

So the compressor was actually dead on this one, so I stuck a new relay on, I heard the compressor make several clicks and attempt to come on, however it did not stick, this indicates that there was a mechanical failure inside the compressor itself.

End of story…

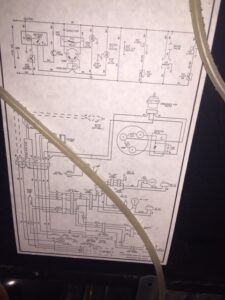

If you look at the photos you will notice one with a sheet of paper with strange drawings, that is known as a schematic on top and a wiring diagram on the bottom, this is what we techs use to troubleshoot appliances.

This is the roadmap to success in regards to fixing any machine, it gives use the circuits to test in order to draw conclusions in our diagnostics they are not easy to read at first but with time it gets easier.

Everyday I learn more about schematics, it is a never ending tunnel of knowledge.